Leak Management Program

Leaks in Compressed Air Systems is nothing but Wasted Energy!

Compressed air systems typically lose 25%, or more of their supply through leaks. Leaks are not only wasted energy, but they are also significantly expensive and contribute to increased CO2 emissions.

A LeekSeek leak audit and repair has proven to be the most effective and cost-efficient method in the market.

The LeekSeek® Leak Management program provides maximum and sustainable leak reduction to save energy and reduce carbon emission.

First, we locate, document and report the leaks…

LeekSeek audits are always carried out by LeekSeek® certified technicians.

Your whole network, piping, connections, valves, machines, is checked for leaks using an ultra-sonic leak detection instrument with DND® (Dynamic Noise Discrimination) technology. Each detected leak is tagged, evaluated and all valuable data is reported into the LeekSeek proprietary online management software.

… then we eliminate them!

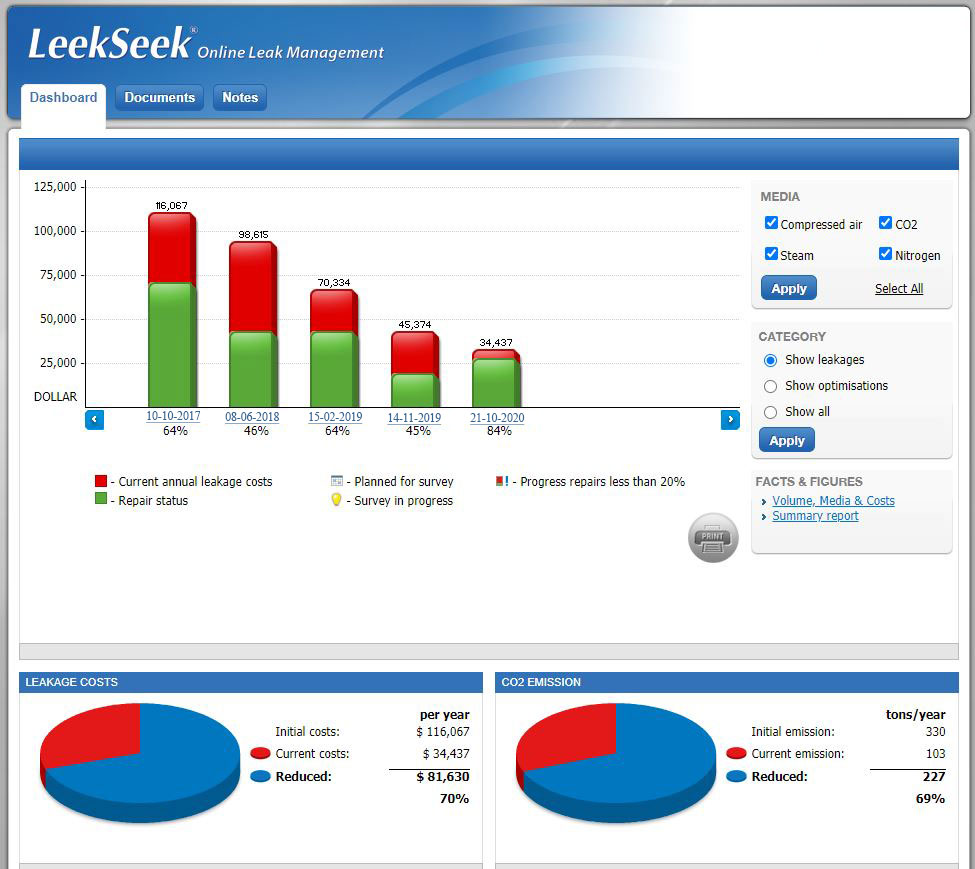

The software tool gives you simple and fast information on where exactly leaks are located within your plant, which media is leaking and the severity of the leaks. It provides all necessary data for the plant management to monitor the safety related to gas leaks within and around your plant. The software also provides you with tools for prioritized repair actions, including estimated time, required components, and more.

Thanks to our unique methods of documentation, our intelligent reporting software, most of the repairs are very often completed at the same visit as the audit, and during normal production hours, depending on each individual plants´ accessibility.

N2

Nitrogen

Argon

Argon

H2

Hydrogen

CO2

Carbon dioxide

He

Helium

CH4

Methane

C3H8

Propane

O2

Oxygen

Steam

Steam

Vacuum

Vacuum

All compressed gases

A standard LeekSeek® audit covers not only compressed air, but includes also all other industrial pressurized gases, such as; Nitrogen, CO2, Hydrogen, Oxygen, Argon, LNG, LPG, Etc…, including Steam and Vacuum. The report will show results in total, as well as detailed information for each gas individually.

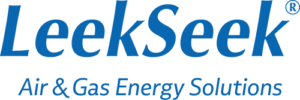

Maximize your savings, start now!

It is not uncommon to ignore air leaks since you can´t see it, most often not hear it, and that leaks may be viewed as “only air.” However, air leaks cost you unnecessary money every minute, until it´s removed. The longer you wait, the repairs are delayed and leaks are allowed to continue, the more potential savings will be lost.

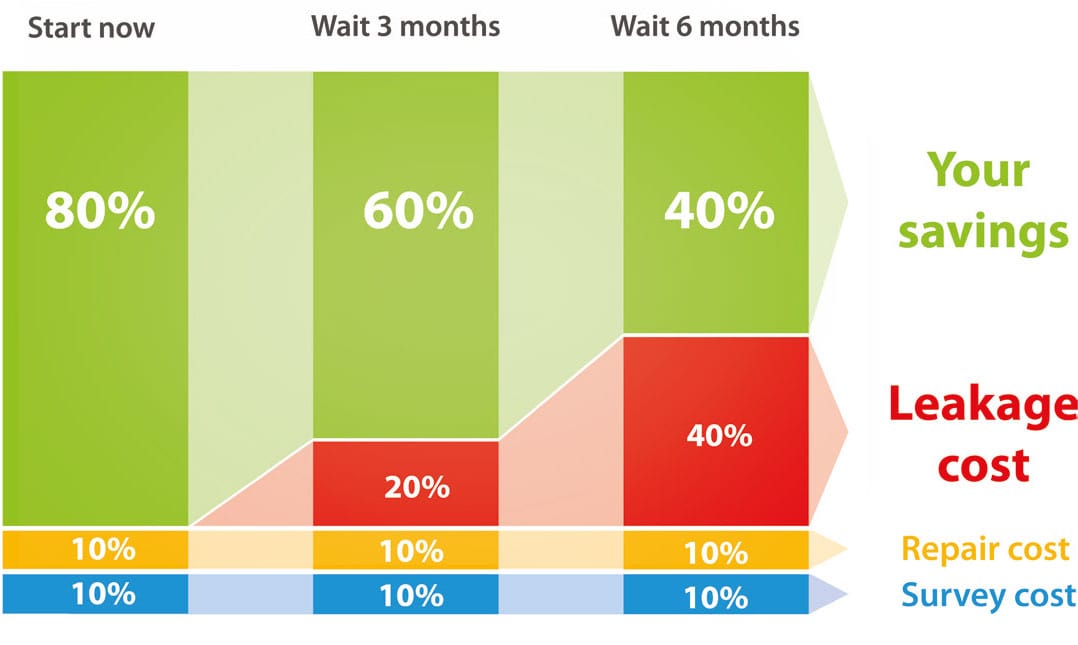

LeekSeek® Energy Labelled Leak Management Program

A standard LeekSeek® Compressed Air Leak Management Program comes with an energy label.

Based on results and improvements in reducing leaks, the client will be awarded with a LeekSeek® energy label after each audit, starting at level D, followed by C, B and finally A!

- Harmonizes with other energy saving measures standards within the industry and the society

- Makes the environmental impact of the Compressed Air Leak Management program more visible

- Creates an incentive long-term sustainable plan to maximize reduction of waste on compressed air

- Makes it easier for clients to follow the progress, development, and improvements within a Compressed Air Leak Management program

LeekSeek®, – the Industrial Standard for Compressed Air & Gas Leak Management!

Calculate your savings

Cubic Meter/Euro

Cubic Meter/Pound

Cubic Feet / U.S. Dollar

Online Quote Request

We would be pleased to provide you with a non-binding and free of charge calculation of your potential savings, investment and payback time.

Please fill out the form and we will then contact your within 24 hours.